Butyl Rubber Products

Sound Damping Sheet

A Sound Damping Sheet is a specialized acoustic material designed to reduce noise and vibration by absorbing and dampening sound energy at the source. It is typically manufactured using a viscoelastic polymer layer, often combined with a high-density rubber or bitumen-based compound, laminated onto an aluminium foil or polymer surface.

Sound Damping Sheets are engineered to deliver effective noise reduction across a wide range of frequencies, especially in areas where metal or rigid panels tend to amplify sound. The strong pressure-sensitive adhesive backing ensures firm bonding to surfaces such as metal, plastic, and composite panels, allowing the sheet to remain stable even under continuous vibration and temperature variations. Its flexible construction enables easy application on flat as well as slightly contoured surfaces without cracking or peeling.

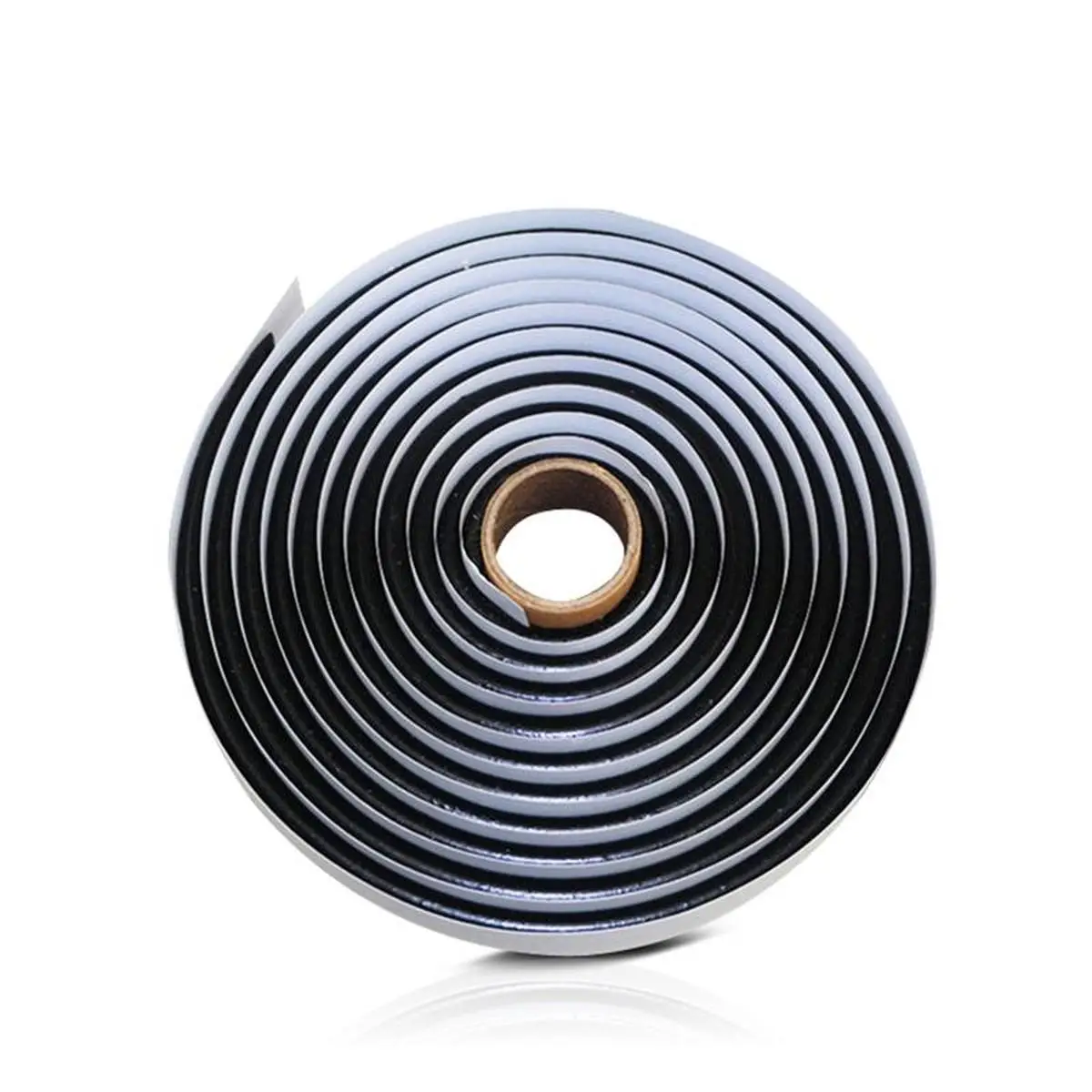

Headlamp Sealant/Strip

Headlamp Sealant / Strip is a specialized sealing material used for secure and moisture-resistant sealing of automotive headlamp and tail lamp assemblies. It is typically manufactured from high-quality butyl rubber–based compounds, supplied in strip or rope form, which remain permanently flexible and non-hardening over time.

It is widely used in automotive manufacturing, headlamp assembly, repair, and refurbishment applications. It is especially preferred for resealing opened headlamps during bulb replacement, modification, or lens repair. Due to its ease of application, reworkability, and long-term sealing performance, this product is a trusted solution for maintaining headlamp clarity, durability, and protection in both OEM and aftermarket automotive applications.

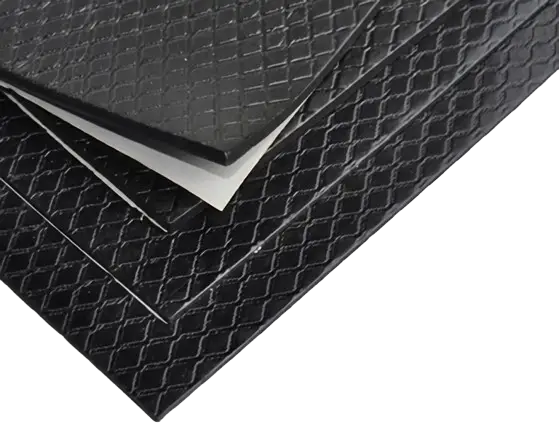

Sound Deadning Sheet

A Sound Deadening Sheet is an acoustic control material designed to reduce unwanted noise by minimizing vibration and resonance in structural panels. It is commonly manufactured using a viscoelastic, high-density polymer or rubber-based compound, often laminated with an aluminium foil or reinforced surface layer.

Sound deadening sheets are engineered for reliable performance under continuous vibration and varying temperature conditions. The pressure-sensitive adhesive backing ensures strong and lasting adhesion to surfaces such as metal, plastic, and composite panels without peeling or shifting over time. Their flexible construction allows easy application on flat as well as curved surfaces, while the dense core material effectively controls low- to mid-frequency noise that typically causes rattling and booming sounds. These sheets are widely used in automotive cabins, commercial vehicles, machinery panels, generator enclosures, HVAC systems, and industrial equipment where noise reduction and improved acoustic comfort are required.

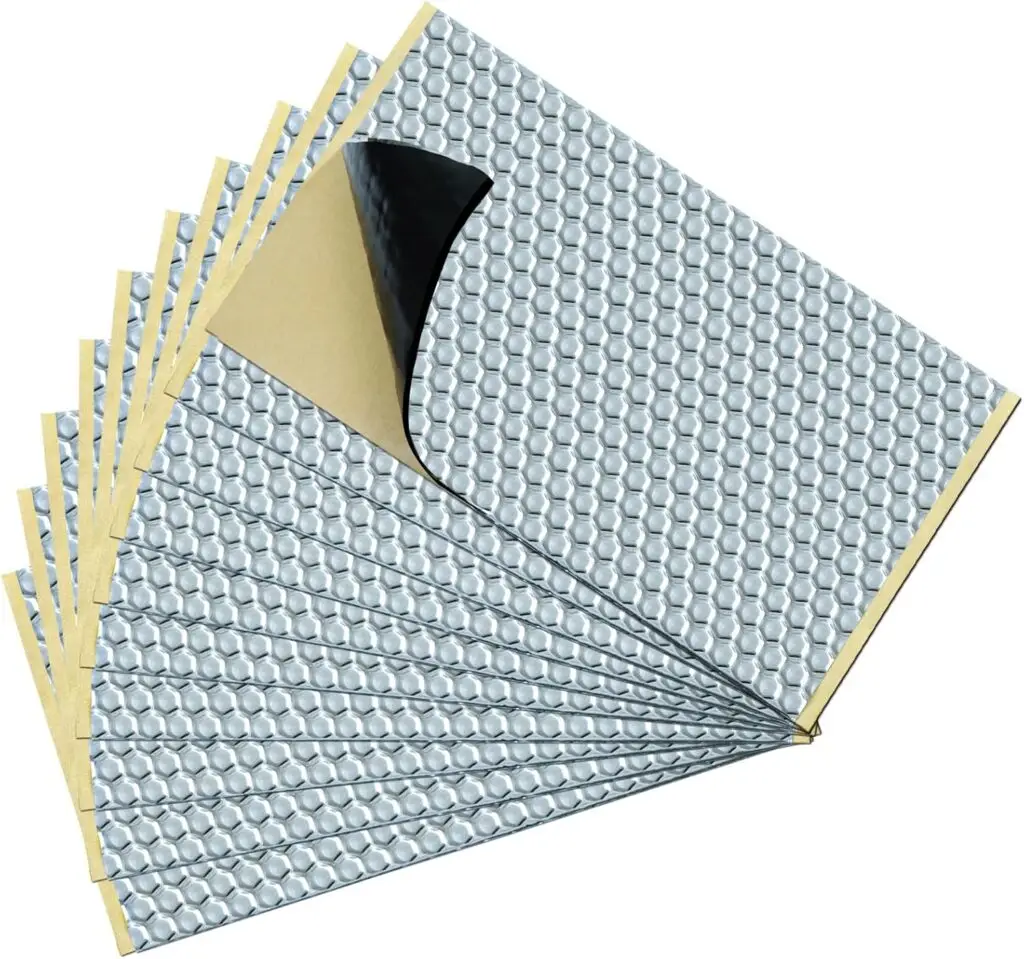

Lightweight Soundproofing and Vibration Damping Panel (QLH Series Colloid)

It is an advanced acoustic control solution designed to reduce noise transmission and suppress structural vibration while maintaining a low overall weight. This panel is manufactured using a specially formulated viscoelastic colloid core combined with a lightweight composite or polymer facing, allowing it to effectively absorb and dissipate vibrational energy. The engineered colloid material converts mechanical vibration into minimal thermal energy, helping to control resonance and reduce airborne as well as structure-borne noise at the source

The QLH Series panels are designed for stable performance across a wide range of operating conditions. Their lightweight construction makes them suitable for applications where added mass must be minimized without compromising acoustic efficiency. The material offers strong damping characteristics, good adhesion compatibility with common substrates, and resistance to deformation under continuous vibration. The panel structure ensures long-term reliability, maintaining damping efficiency even under temperature fluctuations and prolonged operational stress.

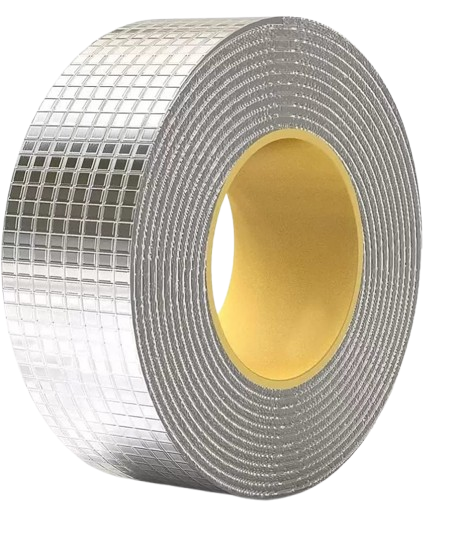

Single-sided aluminum foil waterproof sealing tape/master rolls

Single-Sided Aluminum Foil Waterproof Sealing Tape / Master Rolls are high-performance sealing materials designed for waterproofing, insulation, and surface protection applications. The tape is manufactured using a durable aluminium foil backing laminated with a strong pressure-sensitive adhesive, typically rubber-based or modified bitumen-based, which provides excellent bonding to a wide range of substrates.

This sealing tape is engineered for reliable performance in demanding conditions. The single-sided construction allows easy application on flat or slightly irregular surfaces, forming a continuous and leak-proof seal. The adhesive layer delivers high initial tack and long-term adhesion, helping the tape maintain sealing integrity even under temperature variations, humidity, and outdoor exposure. The aluminium foil backing also provides dimensional stability, preventing tearing and maintaining coverage over joints, seams, and overlaps.

ASA coated waterproof sealing tape/master rolls

The automotive headlamp sealant strip is made primarily from butyl rubber, combined with other additives and processed through advanced technology. It is a non-curing, self-adhesive waterproof sealant strip with strong bonding ability to various surface materials. It also offers excellent weather resistance, aging resistance, and waterproof properties, providing sealing, vibration reduction, and protection for the adhered objects.

PVDF waterproof sealing tape/master rolls

Based on existing automotive soundproofing and vibration damping technology, we have developed automotive-grade vibration damping products specifically designed for OEMs, suitable for passenger cars, commercial vehicles, and especially new energy vehicles. The damping sheet is made by combining high-elasticity, high-adhesion butyl rubber with aluminum foil. Our soundproofing damping sheets have been adopted by multiple OEMs, offering customized solutions to meet automotive-grade requirements, combining functionality, cost-effectiveness, and environmental benefits.

Upgrade your driving experience today with our Damping Sheet and enjoy a quieter, more enjoyable

journey on the road. Silence the noise and rediscover the joy of driving

These damping sheets are engineered to absorb and dissipate vibrations, providing effective

control over unwanted resonances. Say goodbye to rattling, humming, and disruptive vibrations

Elevate Your Audio Experience with Our Advanced Damping Sheets! Immerse yourself in crystal

clear sound, where every note is felt and appreciated. Our cutting-edge damping technology

ensures you enjoy the richness of every melody

Roof flashing tape

Roof Flashing Tape is used as a reliable waterproofing solution in both new construction and repair applications. The tape is typically manufactured with a durable polymer or metal-reinforced top layer combined with a high-performance pressure-sensitive adhesive, commonly butyl rubber–based, which provides strong bonding to roofing substrates. This construction allows the tape to form an effective barrier against water penetration at vulnerable roof details.

The adhesive system is engineered to maintain long-term sealing performance under outdoor exposure. Roof flashing tape offers good resistance to rain, UV radiation, temperature variations, and environmental aging, ensuring that the seal remains intact over time. Its flexible structure allows it to conform easily to irregular surfaces, corners, fasteners, and overlaps without cracking or losing adhesion, even when minor structural movement occurs.

Single-sided non-woven waterproof sealing tape

Single-sided Non-woven Butyl Rubber Tape is a self-adhesive waterproof sealing tape with butyl rubber as the base material and a non-woven fabric surface coating. The product offers excellent initial adhesion, compatibility with diverse substrates, and easy installation. It remains non-curing, retaining long-term flexibility to accommodate structural movement, while providing superior waterproof sealing, corrosion resistance, and extended weather durability.

This product is designed for sealing connections at roof ridges of light steel factory buildings,

joints between color steel plates and skylight panels, drainage gutters, as well as waterproofing interfaces

around window/door frames and walls, concrete roofs, and ventilation ducts.

Photovoltaic Double-Glass Butyl Sealant Strip

This product is a key material for packaging new photovoltaic cells (such as HJT and perovskite). With high gas impermeability and low water vapor transmission rate (<0.01 g/m²/day), it protects against environmental erosion, preventing perovskite degradation or HJT cell oxidation, ensuring module stability. It has strong weather resistance (-40°C to 120°C), is compatible with lamination processes, and prevents damage to sensitive materials. Compared to traditional EVA/POE films, butyl rubber enhances barrier performance by 1-2 orders of magnitude and suits flexible modules