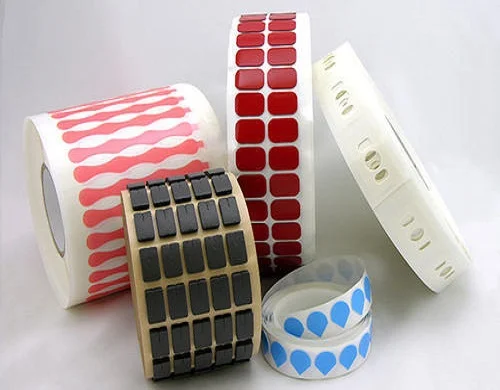

Die-Cut Solutions

Foam Die Cut

KIPL is one of the leading Foam Die Cut Manufacturers in India. We provide industry-ready custom foam die cuts through our established work in industrial applications.

Die cut foam is a precision-shaped material produced using advanced die-cutting processes to meet specific protection, cushioning and insulation requirements. It is widely used as a core packaging and component-support solution in both automotive and industrial sectors due to its durability, versatility and excellent shock-absorbing properties. Our company offers customized foam die-cut solutions with consistent quality, reliable supply and dedicated customer support. We provide a wide range of foam die cuts designed to improve product safety, enhance performance and ensure efficient handling across various applications.

Types of Foam Die Cut

- Polyurethane Foam: The flexible foam material serves as a production basis for various products ranging from automobile seats to furniture cushions and mattresses. Resistance within this material is high, but comfort, together with exceptional durability, remains outstanding.

- Polyethylene Foam: This material serves as packaging foam because it remains durable while being resistant to water. Polyethylene delivers excellent shock protection and provides resistance to both chemical substances and water damage.

- EVA Foam: Users select EVA foam because it gives both elastic adaptability and shock-resistant properties along with its supple feeling, thus earning popularity for sports accessories and footwear and packaging solutions.

- Polypropylene Foam: The rigid foam substance stands out with its chemical-proof properties and lightweight structure, which makes it suitable for packaging applications along with insulation duties and automotive needs.